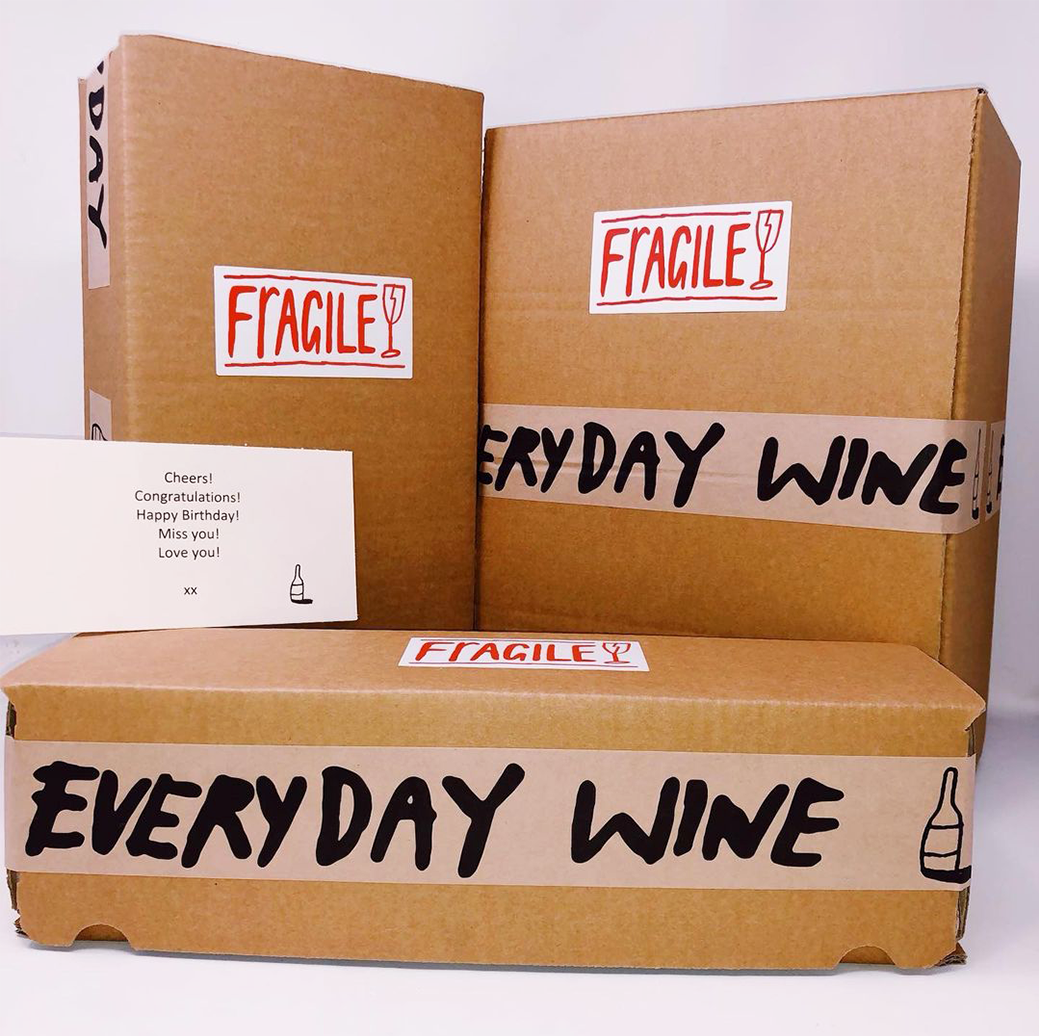

Kraft boxes and noissue custom tape by @everydaywine

When it comes to ordering the right ecommerce box for your business, size matters.

As the final and all-important step in the fulfillment of a sale, the packaging your product is delivered in ensures it’s delivered safely and attractively to your customer (see: the unboxing experience).

The size of the box you select in relation to your product size plays a big role in this. In this article, we’ll cover:

- How to choose the correct size box for shipping

- How to measure a box for shipping

- How to calculate the dimensional weight of a box.

Why is it Important to Choose the Right-Sized Shipping Box?

1. It protects your products. Using the wrong-sized shipping box means your products are less secure for shipping and creates the risk of them becoming damaged in transit or lost.

2. It saves you money. Choosing the right-sized box ensures your shipping rates are as efficient as possible. Shipping is often charged by the space the package occupies in transit rather than the weight of the parcel. If you’ve got a small item in an oversized box, you’re not being as cost effective as you could be.

3. It’s a sign of excellent customer service. Having the right sized box looks more professional to your customer and reflects more favourably on your brand than one that’s the wrong size.

When you’re purchasing a shipping box, the measurements you’ll see displayed on a packaging provider’s website for a shipping box are always the box’s inside dimensions.

This is so you can accurately assess whether your products will fit inside properly. Packaging companies like noissue show box dimensions in LxWxH, or length times width times height. This is usually displayed in millimeters or inches.

To assess what box size is best for your business, you’ll need to have the products you’re looking to ship and a ruler or tape measure on hand.

How to Choose the Correct Box Size for Shipping

1. Measure the length, then width, then height (LxWxH) of the product that will be going in the box and compare these measurements to the shipping box sizes available.

2. Remember to account for any interior packaging going inside the box, like custom tissue paper or a custom card insert. There needs to be enough space to fit both your product and these additional packaging layers within the box.

3. Choose a box size that’s larger in its measurements than your product and interior packaging combined. You want to make sure that your product is contained within the box flaps, and not spilling out over them or taller than the box itself.

4. You may end up with void space around your product. Fill the space with a material that cushions your product so it doesn’t slide around in transit. There are plenty of sustainable alternatives to bubble wrap you can use, including compostable tissue paper or kraft paper.

Once you’ve received your boxes and you’re measuring them for shipping with a carrier like FedEx or UPS, you’ll need to measure the outside dimensions of the box. This is so your chosen shipping carrier can calculate the space required for your packages in transit.

How to Measure a Box for Shipping

1. Make sure your box is sealed with its flap closed, and then use your ruler or measuring tape to measure the longest side of the box, end to end, to get the length. This is the most important dimension to get right, as shipping carriers use it to determine shipping rates and whether a package is oversized.

2. Next, measure the width of your box on the shortest side. Box width is unlikely to impact on shipping costs, as it’s generally shorter than the box length.

3. Turn your measuring tool vertically to measure the standing height of the box. Again, as a smaller metric, this measurement is unlikely to contribute to a change in shipping costs.

How to Calculate the Dimensional Weight of a Box

The dimensional weight of a package is also called volumetric weight or cubed weight. It refers to a package’s density and it’s used by carriers like FedEx and UPS to determine a package’s shipping costs. Where in the world you’re shipping the package to will also affect these costs. This is how you can calculate it.

1. To calculate the cubic size of a box, multiply its length by width by height (LxWxH). For example, if your box is 15 inches x 12 inches x 2.75 inches, it will be 495 cubic inches.

2. Next, divide the box’s cubic size by your chosen freight carrier’s dimensional factor, or DIM divisor. This is a number set by carrier companies that represents cubic inches per pound. FedEx’s divisor is 139 for domestic shipments and UPS’ divisor is 139 for domestic shipments over one cubic foot in size. For shipments that are under one cubic foot, UPS’ divisor is 166.

3. The number you end up with will be your box’s dimensional weight, in pounds.

Pro tip: Dimensional weight pricing will vary by carrier. Dimensional weight is also different from the actual weight of a box. Carriers like Fedex and UPS calculate shipping costs based on whichever number is the biggest out of the two.

Other Considerations For Shipping a Box

1. Use eco-friendly packaging materials.

When you select shipping boxes, it’s important to consider their end-of-life disposal and the way that impacts on the environment.

Ecommerce packaging waste has a massive impact on the environment, with plastic from ecommerce packaging estimated to reach 4.5 billion pounds by 2025. This type of packaging can't be reused or recycled and takes hundreds of years to break down in landfill.

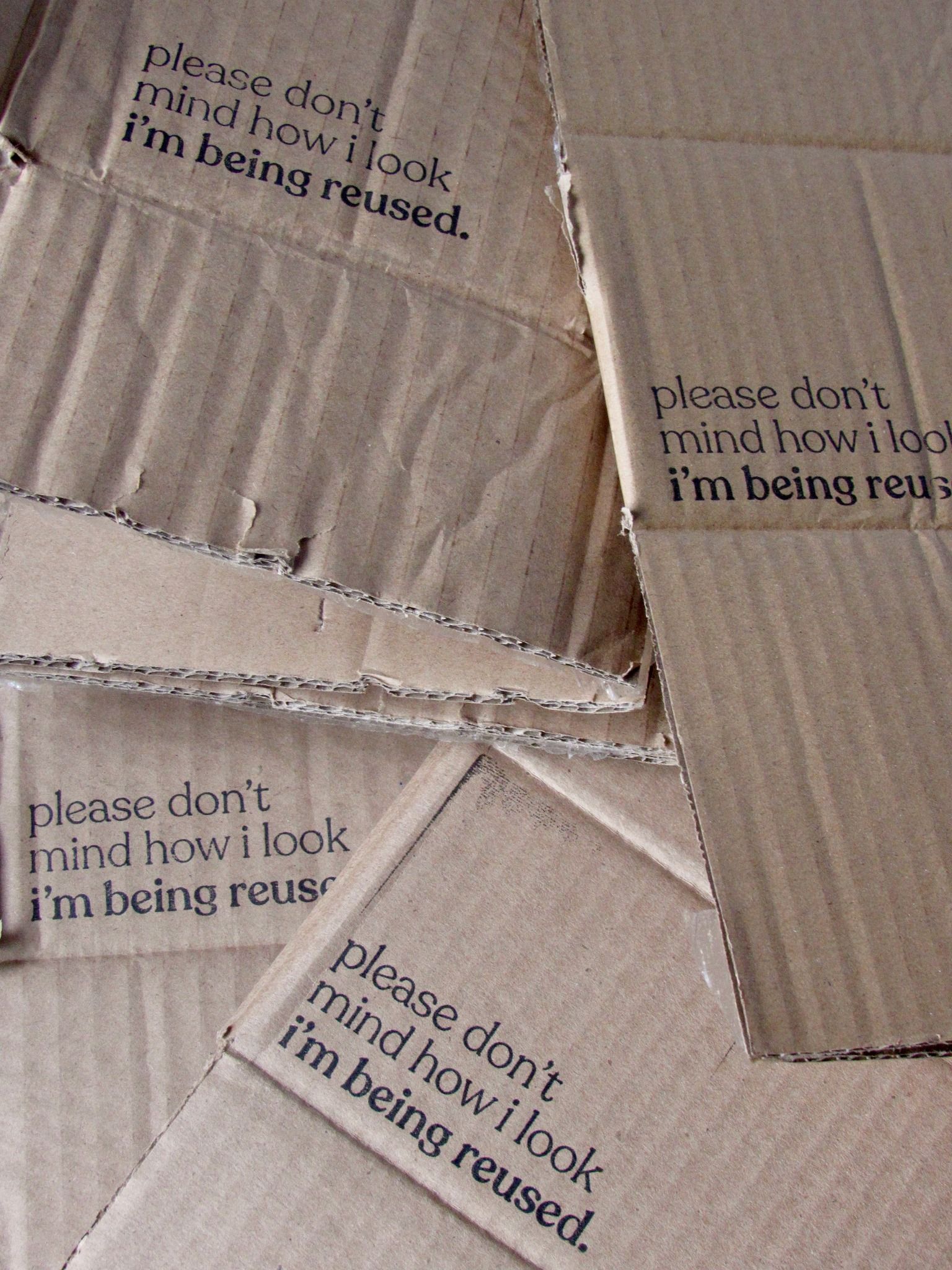

Boxes made from eco-friendly packaging materials like recycled cardboard can be composted or curbside recycled after use, which is a lower impact option than single-use boxes that contribute to the waste being sent to landfill.

Corrugated boxes made from recycled materials like cardboard are also a strong, durable option, which means your products will remain safe.

Using sustainable packaging also improves your brand’s perception with customers. 74% of consumers aged 18 to 34 are also more likely to purchase a product if it and its packaging go beyond single use or are eco-friendly by design and disposal.

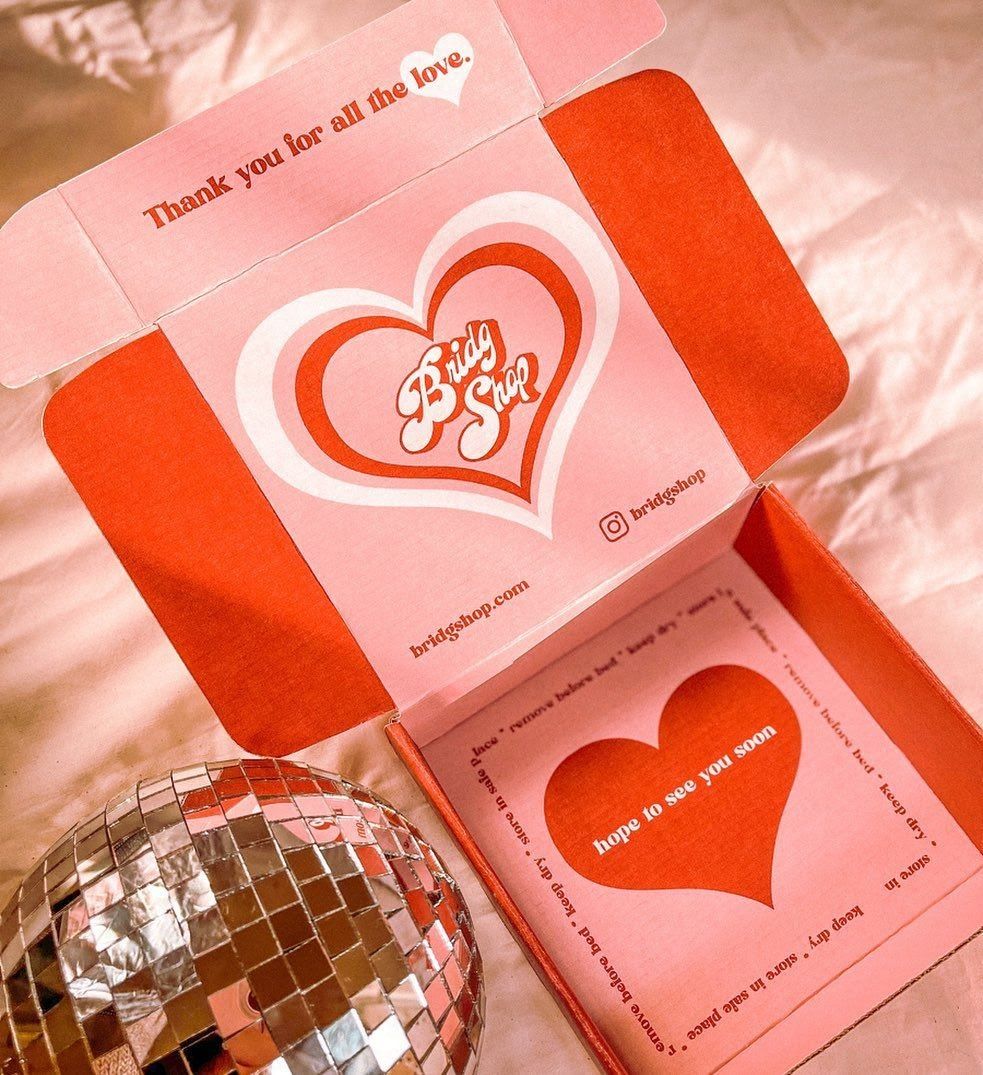

2. Customize your box to showcase your brand.

Creating a custom box improves product presentation and can turn your package into a branded and immersive experience. Get creative with your design and try out a repeating logo, bold typography, your brand colors or a call-to-action for your customer.

Branding your packaging can play a key role in encouraging repeat purchases and social sharing of your products. 30% of businesses report an increase in revenue after improving product packaging, so its importance can’t be overstated.

If you’re looking for a cost-effective option, consider pairing a stock box with packaging options like custom stickers, custom tape or custom stamps to create a pop of branding on the exterior of the box.

Final Words

Getting the measurements right so you order and ship the correct box size is incredibly important to protect your products, showcase your customer service and save your business money on shipping.

Follow the steps above, and your brand’s boxes will be the best in the business in no time!

noissue creates custom and stock packaging products for brands that are designed online and delivered worldwide. Check out noissue's range of Custom and Stock Boxes, Shoe Boxes, and more to get started with shipping boxes today!