noissue Custom Tissue Paper by @frecklstudio

At noissue, we know a fair bit about paper – after all, the first packaging product we launched was custom tissue paper! We've spent a lot of time refining our process on how to create the most affordable and highest-quality printed products for businesses.

We receive many questions about fabric and paper weight from customers who are new to custom-printed goods.

In this guide, we'll explain the meaning of GSM and how it relates to our custom tissue paper and custom tote bags. We've also included a few handy design tips to help you decide which paper thickness and material weights are right for you!

What Does GSM stand for?

The term stands for Grams per Square Meter. The GSM measurement meaning refers to fabric or paper thickness and weight. The GSM value is measured from a single sheet of paper or fabric that measures one meter by one meter in length.

What is paper GSM?

GSM measures the thickness of paper. This standard measurement is crucial in the printing industry to determine the type of paper used for different projects. While GSM is the most commonly used unit globally for measuring a paper's thickness, you might also hear terms like "points" or "mils" in the US, where one-thousandth of an inch is used as a unit of measurement.

The paper weight chart ranges from lightweight tissue paper (such as noissue's 17 GSM custom tissue paper) to heavier paper designs made of cardstock (such as noissue's 350 GSM uncoated custom cards).

Put simply, the higher the GSM, the thicker the paper. However, a higher GSM doesn't always mean better. Understanding paper thickness and weight helps you find the perfect balance between durability, functionality, and aesthetics.

If you don't know the difference between GSM scores, you might end up ordering the wrong paper thickness for your needs. This can be a costly mistake for any business!

So, how do you measure paper weight and thickness? Take a look at our guide below.

Paper thickness GSM guide

The paper weight conversion chart below will give you a better idea of how different weights of paper are typically used.

- 35 - 55 GSM paper: The thinnest paper form, mainly used for newspapers.

- 90 - 120 GSM paper: The average weight of regular copy paper and non-fiction book pages.

- 130 - 250 GSM paper: The weight most commonly used for flyers and promotional posters.

- 260 - 300 GSM paper: Thicker paper but still bendable cardstock, which works well for high-end brochures or magazines.

- 350 - 450 GSM paper: The heaviest and most rigid card, which will easily stand under its own weight. Most commonly used for business cards, greeting cards, postcards, and invitations.

How to Convert GSM Paper Weight to Pounds

This paper weight chart can be handy when using printers that measure in pounds instead of GSM.

100 GSM paper = 67 lbs

120 GSM paper = 81 lbs

200 GSM paper = 135 lbs

250 GSM paper = 168 lbs

300 GSM paper = 202 lbs.

What is GSM in Fabric?

This measures the thickness of a sheet of fabric. Denser textiles like melton wool will have a higher rating, while sheer materials like lightweight cotton will have a lower GSM. noissue's custom tote bags are 248 GSM, which puts them in the medium range for fabric.

Unlike a sheet of paper, a fabric's thickness doesn't always reveal its weight. Fabrics with different weaves or fibers may have the same weight but can vary in thickness.

Understanding Fabric Thickness

The chart below will give you a better idea of the weight of different types of fabric.

67.81 – 135.62 GSM fabric: Sheer fabrics, such as lightweight cotton.

196 – 406.87 GSM fabric: Medium weight fabrics, such as denim.

508.58 – 700 GSM fabric: Heavyweight fabrics, such as towels and melton wool.

How we use GSM in our Custom Packaging

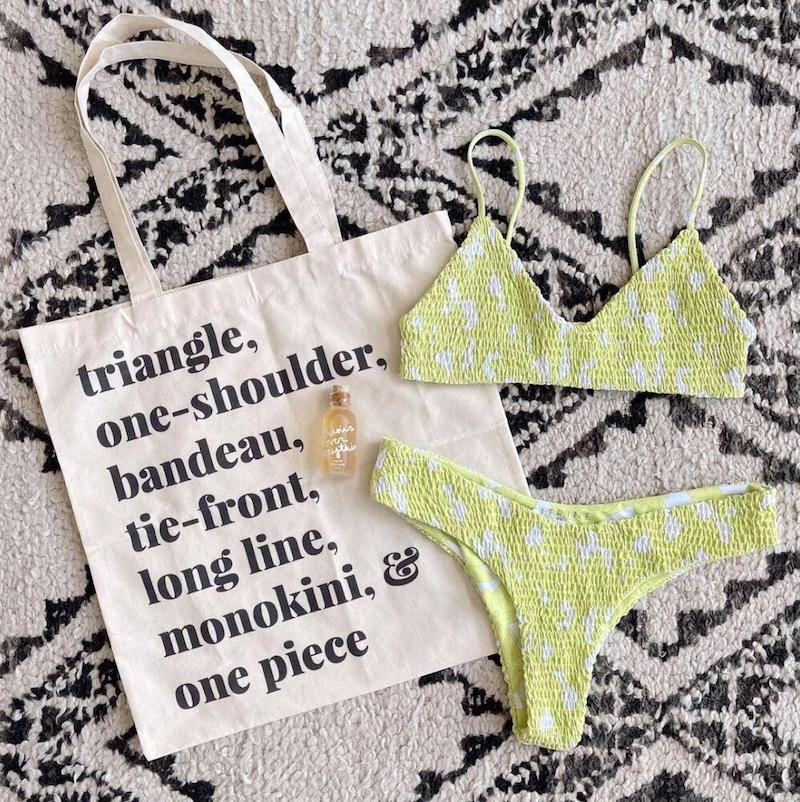

noissue's custom tote bags are available in one size—248 GSM. They're made of a Global Organic Textile Standard (GOTS) cotton material that is lightweight but strong and can safely carry up to 44lbs (20kg). As a medium-weight fabric, they can hold lots of products and are resilient enough to be reused again and again.

Our Custom printed Tissue Paper comes in two paper weights: 17 and 28 GSM. All of our tissue paper is acid-free and sourced sustainably from Forest Stewardship Council (FSC) certified forests. This ensures high-quality and eco-friendly custom packaging for our customers.

What is the Difference Between 17 and 28 GSM Tissue Paper?

There is a subtle difference in the finish between our custom tissue options. 17 GSM is the lightest weight and has a lovely translucent finish. 28 GSM is a slightly thicker type of paper with a more traditional wrapping paper look and feel.

Which Tissue Thickness is Better for my Purposes?

The MOQ (Minimum Order Quantity) for our custom tissue paper is the same for both types of paper and starts at 250 sheets. So, the answer to this question really depends on the look and feel you want to channel for your brand.

Because our 17 GSM tissue paper is quite sheer, it can be used to give customers a cheeky preview of their purchase, letting you create some snazzy effects.

Using a single color pattern on 17 GSM gives your custom tissue a minimalist and striking look.

If you have a more colorful design in mind for your custom tissue paper, the 28 GSM paper weight will show this off to the fullest vibrancy. For this reason, we usually advise customers wanting sheets with a two-color or multi-color design to choose the 28 option—our heavier paper weight.

We use eco-friendly soy-based inks for printing, which produce more intense colors, as well as the Pantone Matching System in our online design platform.

Wrapping it Up

Choosing the right GSM paper thickness for your custom printing materials means considering the function of your packaging design and the impression you want to make on your customers.

Now that you understand the thickness and weight of paper and fabric, you are well on your way to choosing the right custom packaging products for your business. The best part is that you can also apply this knowledge to any other printing needs!

Ready to get started with custom printed packaging? Check out noissue's custom tissue paper and custom tote bags!